Weekly_Assignments :

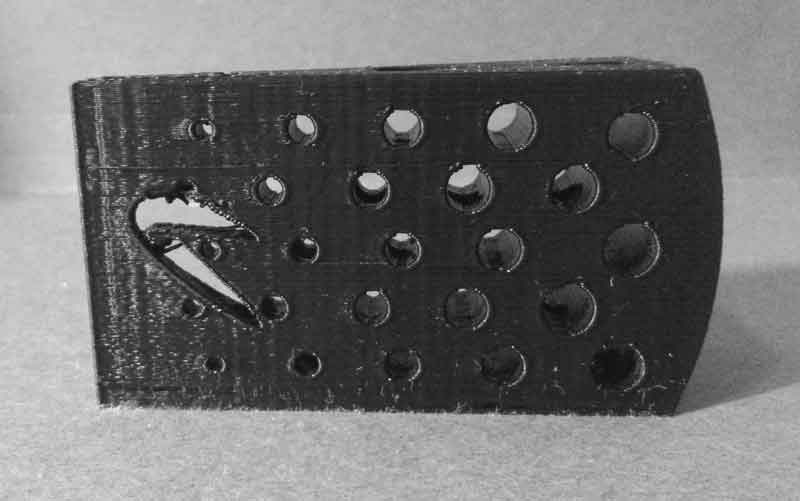

- Design and 3D print an object that could not be made subtractively

- Scan and print an object

#####What I have used:

- ######Design : Solidworks 2015

- ######Scan : kinect xbox360 using skanect software

- ######Slicing : Cura ultimaker

- ######Printed : Falla3D

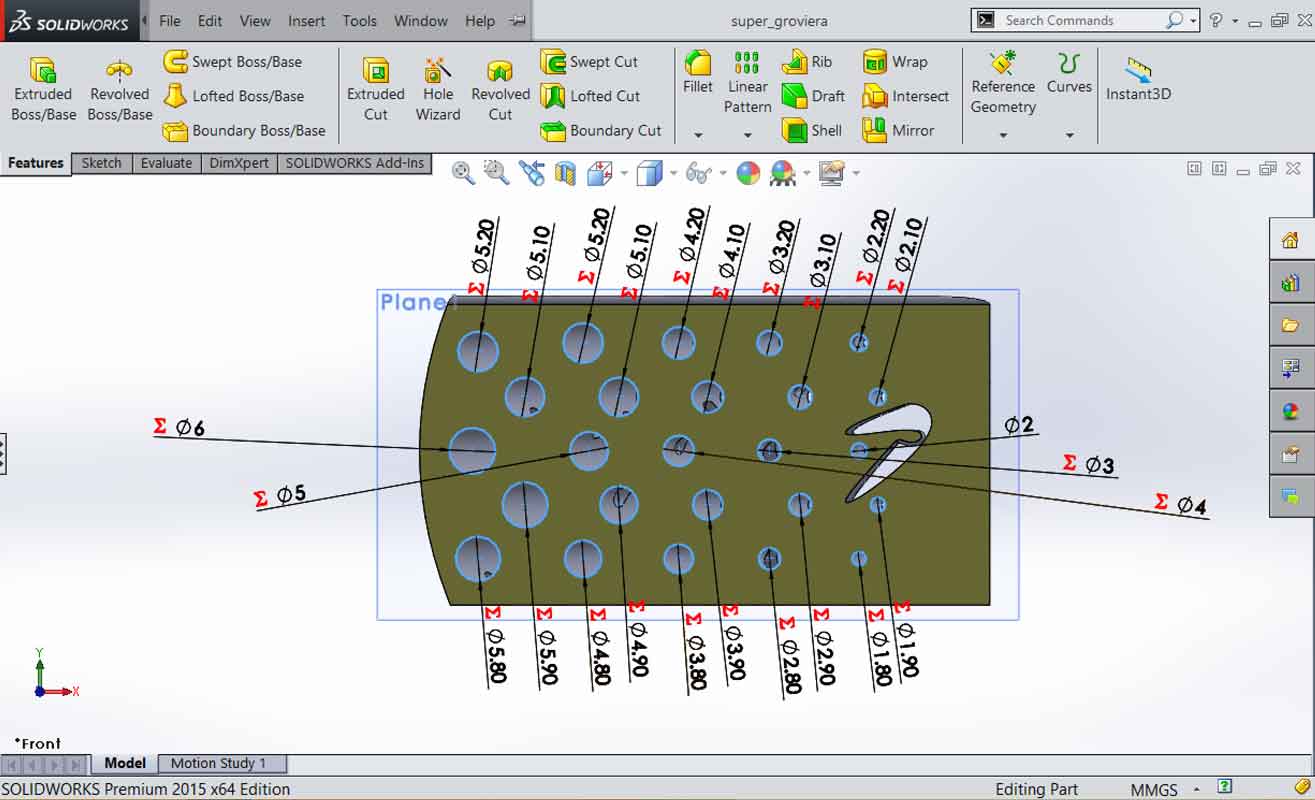

Solidworks design a “superGroviera”

I was looking for a design that would allow me to test the limits of my 3d printer as well as perform the assignment, and to improve my solidworks skill. so I searched in thingverse some inspiration design for test the accuracy of my printer after lots of “overhang hole”

I create a “super groviera slice” cheese GROVIERA style slice, to test the aesthetic outcome of the printer after the execution of overhang hole

- test hole finiture

- test overhang

- complex internal hole geometry, to test the possible “steps loss”

- test external finiture after internal complex geometry

“the hole geometry is parametric! you can change the first hole diameter, and automatically other hole assume +1mm Left +0.1 top -0.1 bottom”

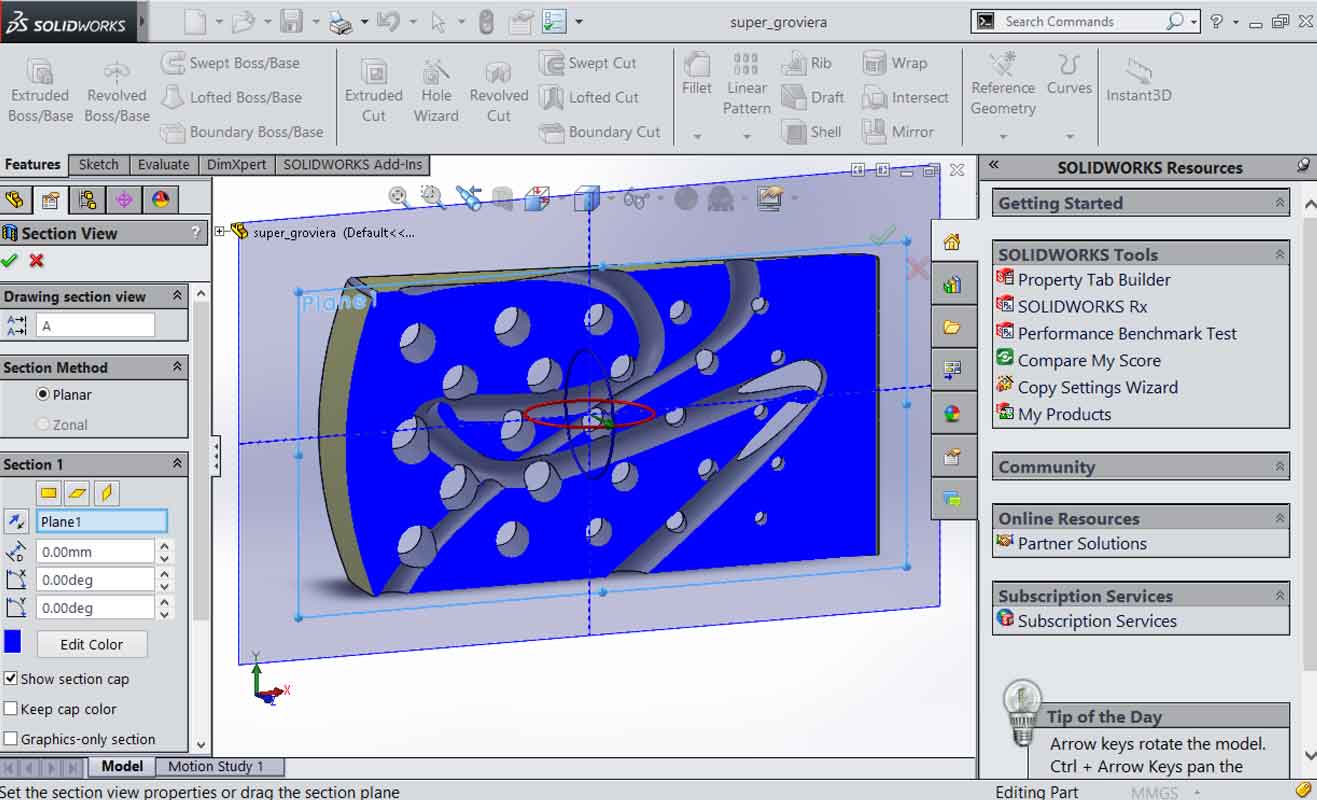

“inside the superGroviera there is 2 tubular profiles which intersect the holes test and create a lots of internal critical overhang “

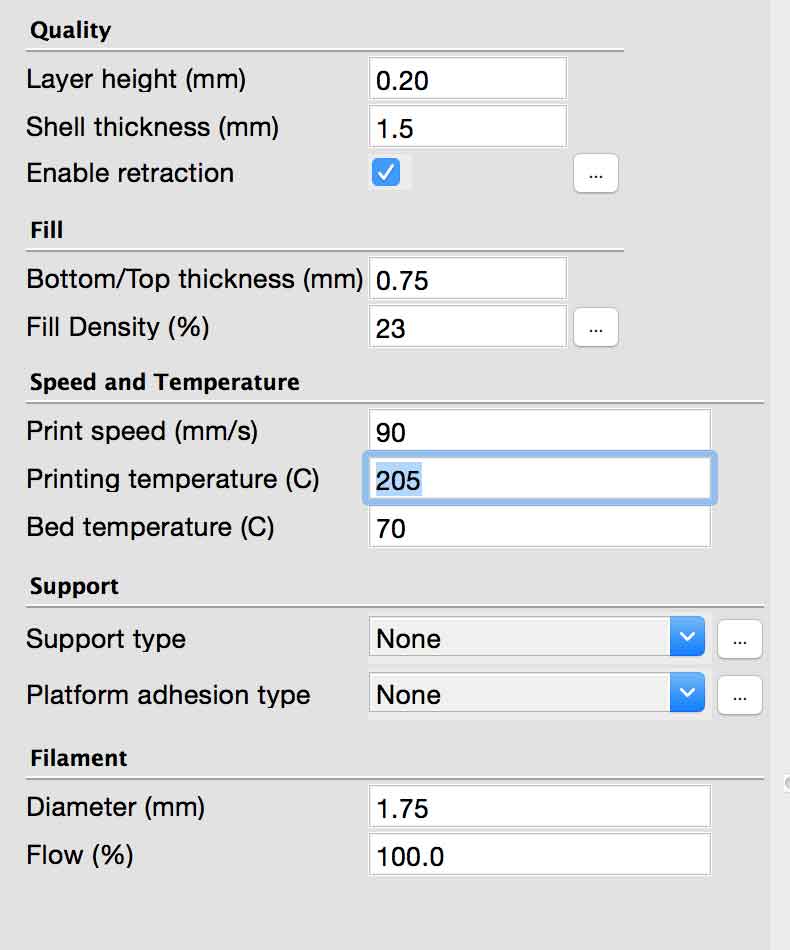

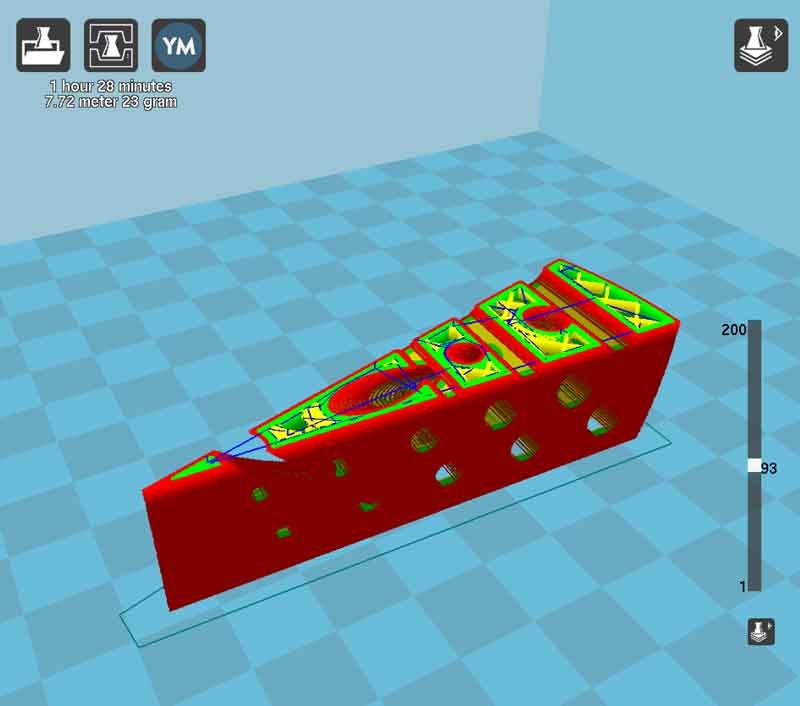

Cura slicing setting

For this assignment I used Cura slicer with this settings:

to improve the external face resolution I lowered the outer shell and top/bottom speed.

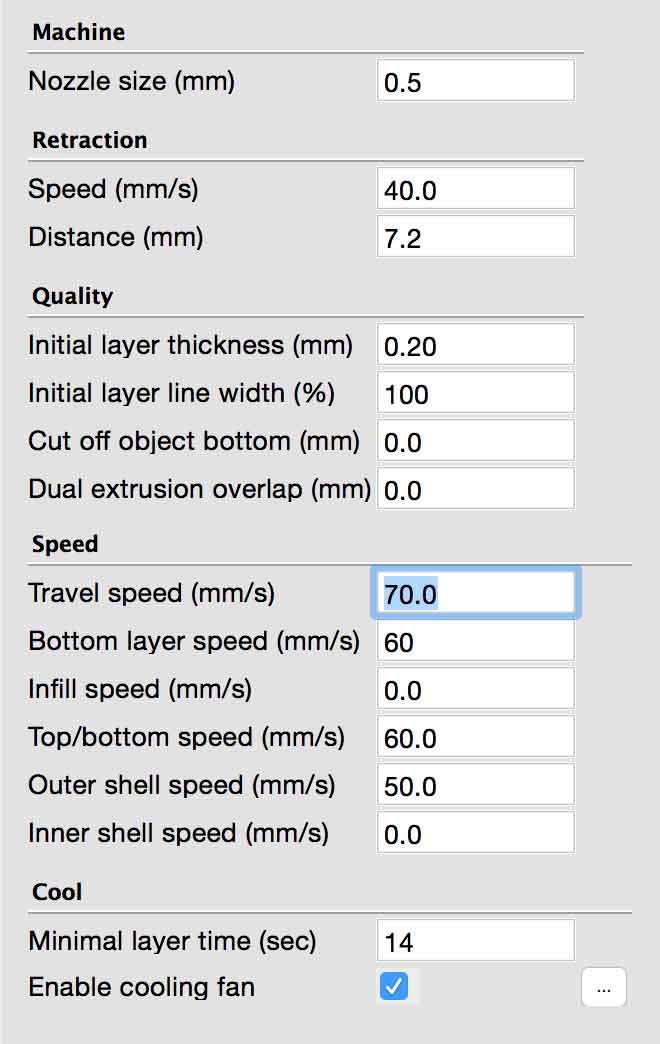

lots of hole overhang! red marked

the preview says 1h and 28min .. that’s ok ! ..is an acceptable time

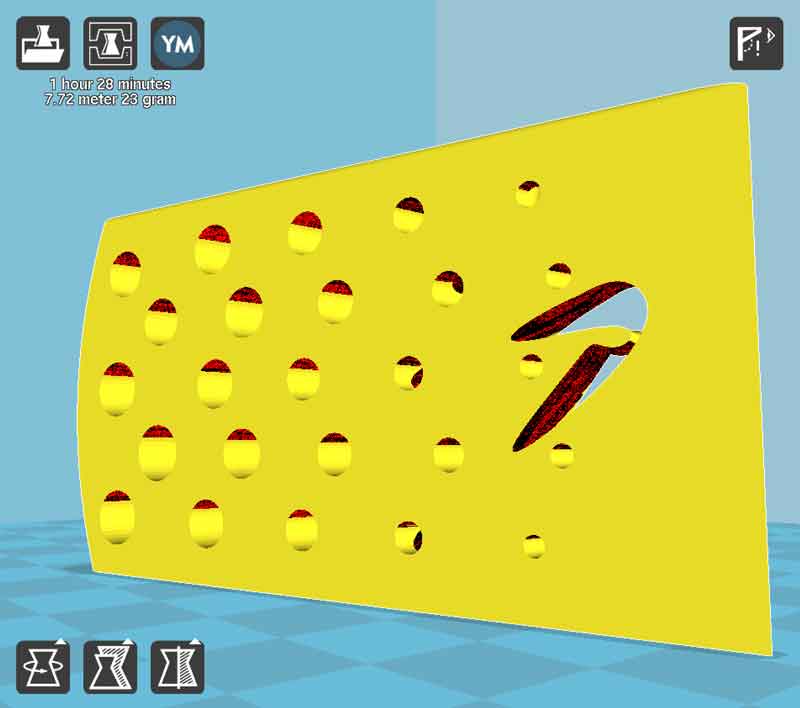

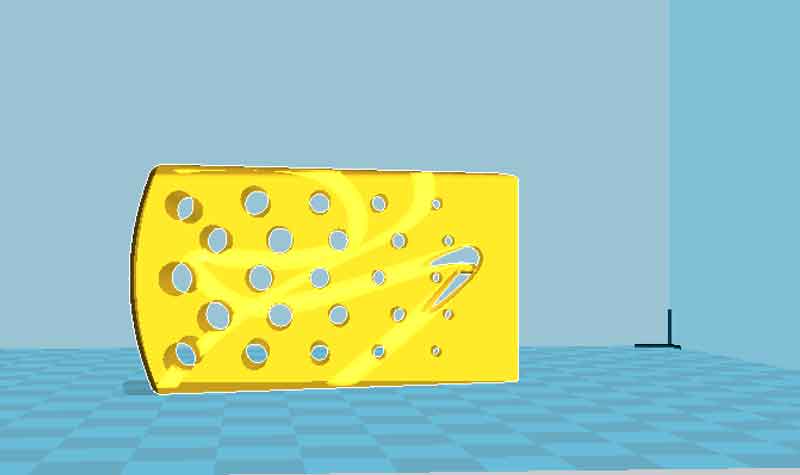

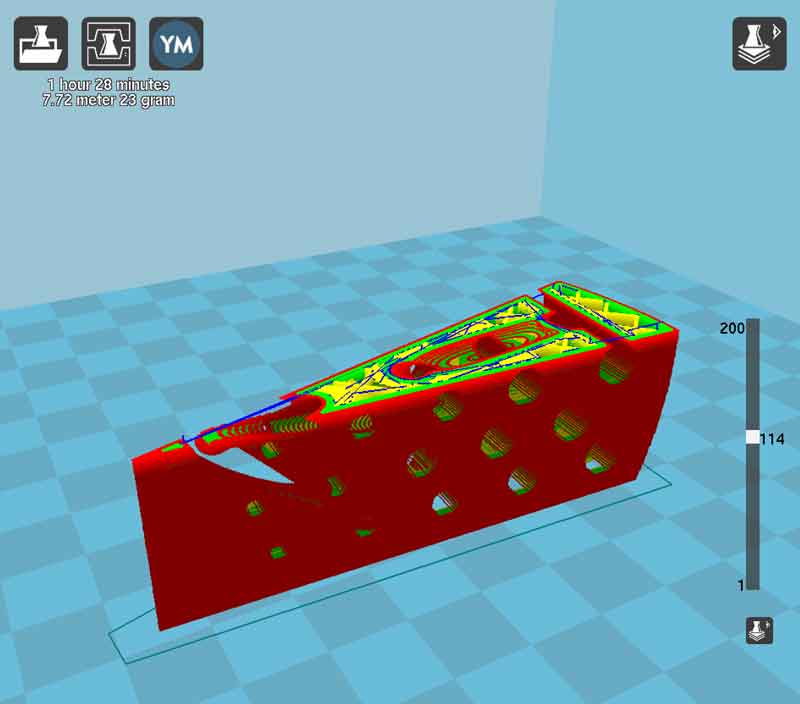

on the top menu, select view mode > Transparent

the internal curved tube profile disturbs and influences the costruction of the external perimeters.

“view mode > Layers”

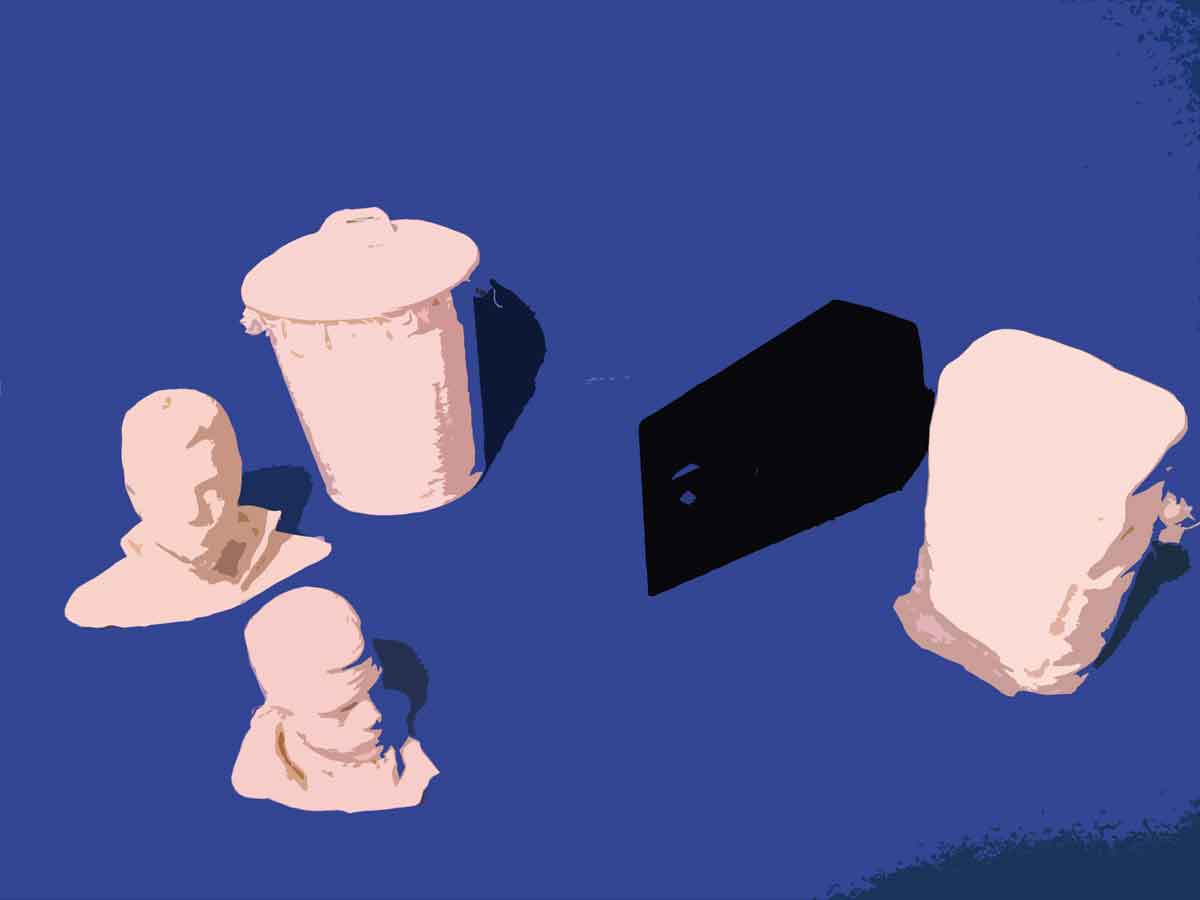

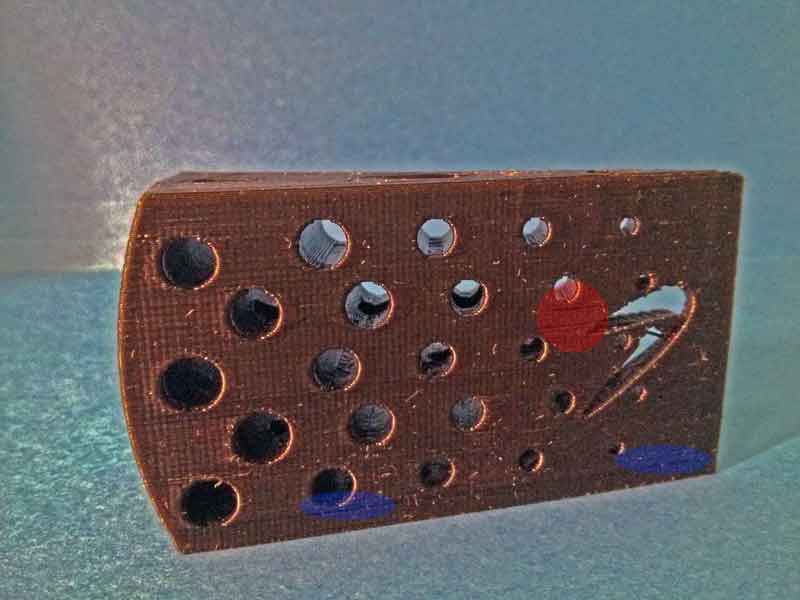

I try to use photoshop to exalt the error of the machine.

- Red marked - error after overhang

- Blue marked - spool block

“more than overhang !”

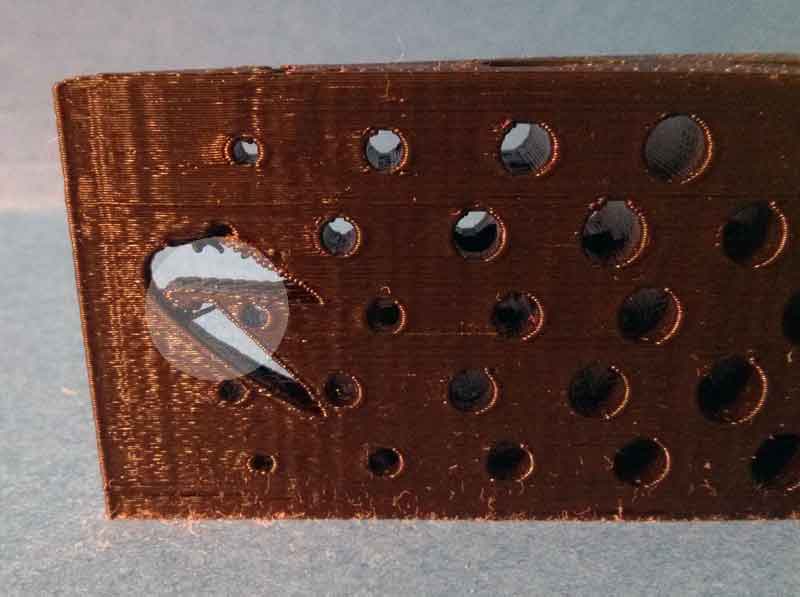

black and white photo..in the first part of the print, you can see “waves of reverb”, due to the high speed printing and possibly extruder temperature too high

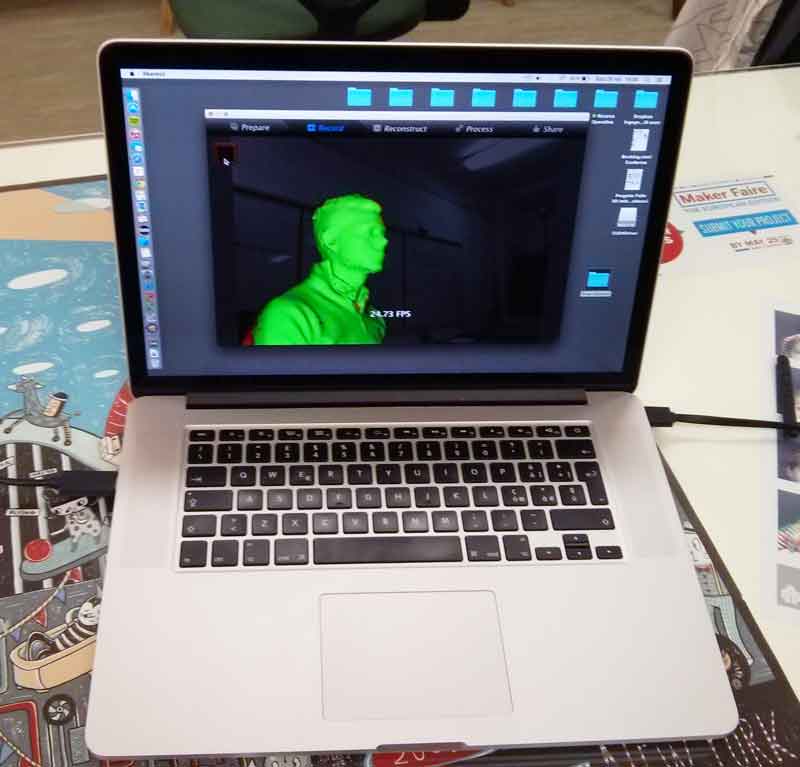

3d scan - kinect Xbox 360

- install nvidia CUDA for enable skanect-GPU

- install skanect

###Start to scan!

With fablab contea guys, I try 2 different type of scan:

- with the subject that turns on itself on a swivel chair moving the kinect from top to bottom

- with subject locked, turning around with the scanect

##Turn itself

save2.obj savetesta.obj

“Saverio can’t stand still if try turn itself with his legs, someone helped me to turn the chair during the scan”

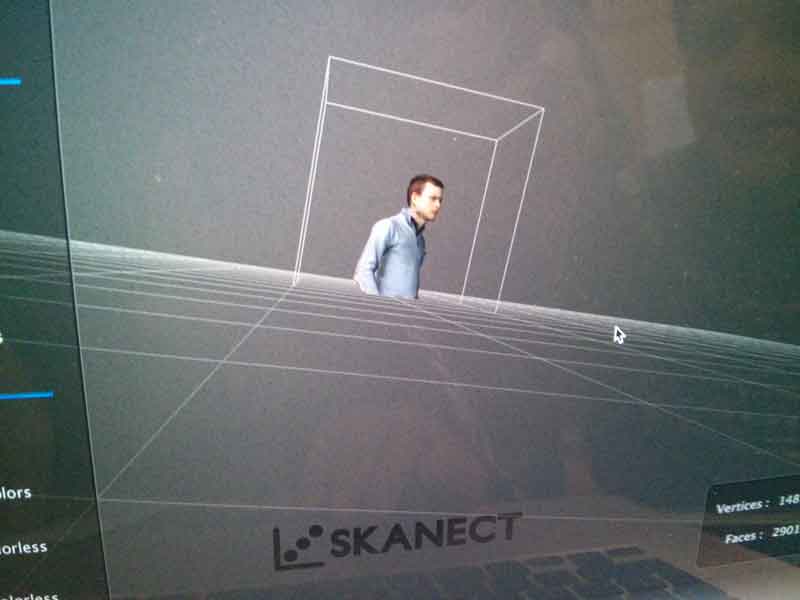

##Subject locked

saveS.obj

“Saverio remains like frozen about a minute while I have scanned him”

“Saverio remain like frozen about a minute while I have scanned him”

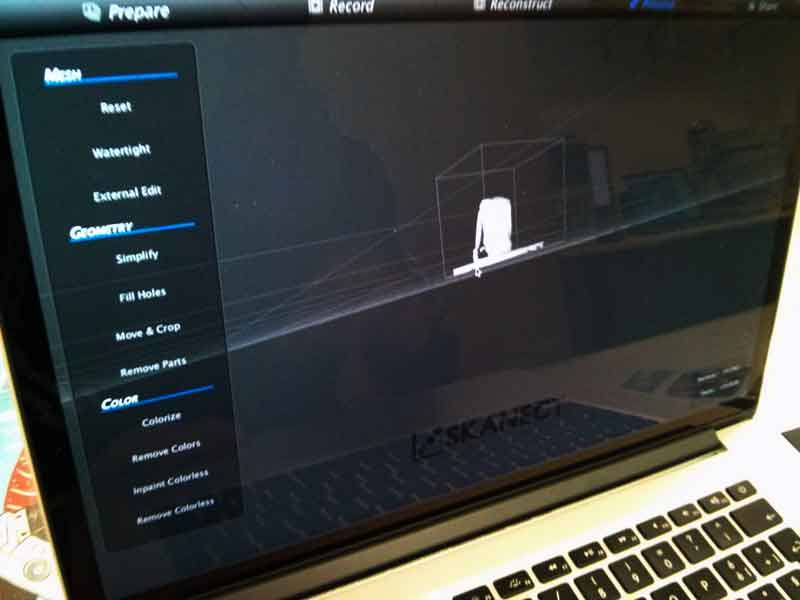

3d printing

I tryed to print the subject loked scan version. I scaled at 0.13 % the scan result, and for improve the print quality, I lowered the layer height at 0.12 using 0.3 mm extruder. In the subject loked scan version was scan face and half body, the time of print at 0.12 LH is 4.00 h, so I decided to ‘cut off object bottom’, for arrive at 1.30 h of print time. During this printing I preferred not using any support type.

“infill = 0% the inside head is empty”

“with (layer height) 0.12, is like impossible see single layer height “

“the final result is good (except for overhang errors), but the scan was scaled too much, so I have lost a lot of definition”

backpack scanSubject locked

“laces bagpack are too small for print it…and broke during the print “

basket scanSubject locked

“Perfect print but again without support material, overhang are visible! “